UNISON - Your trusted partner in surface finishing solutions

We specialize in constructing and producing surface finishing solutions, such as painting machines and robots, painting dryers, and additional painting equipment. Our advanced painting equipment results from many years of experience, and their effective operation allows us to meet the needs of high-quality finishing in many industries.

UNISON products are manufactured in our factory located in Cieplewo, near Pruszcz Gdański. Our team of experts designs and constantly improves finishing equipment to provide customers with comprehensive and modern solutions tailored to their needs.

What makes us stand out? Our people!

After purchasing our devices, we also support our customers, offering remote assistance and service support.

UNISON is not only a manufacturer of finishing and painting robots but also a constantly developing entity. We started our business in 2000 and currently employ about 30 experienced specialists. Our painting solutions are a response to the needs of customers from various industries, including:

- furniture fronts

- furniture elements

- doors

- plates and countertops

- coffins

- plastics

Cooperation with us is a guarantee that you will receive not only technologically advanced finishing machines, painting robots, and dryers, but also the support of our experienced team in selecting the most appropriate finishing solutions for your company. Our painting equipment is intuitive to use, which allows your employees to paint effectively and precisely.

We invite you to cooperate and contact us. Together we can improve the quality of your painting processes, increase production efficiency, and provide your company with a competitive advantage in the market. Choose finishing solutions from UNISON and see how your company reaches new heights of efficiency and quality!

We are experts in producing finishing solutions in Poland and Europe.

Milestones

The beggining

The company founder Wiesław Jackiewicz begins to construct the first machines.

Establishment the UNISON

The company is separated as a fully independent entity. In the same year, the first versions of UNI-SLIM painting machines and the historic UNI-DUO machine were created.

Receiving funding from the EU

UNISON receives funding for the expansion and development of the company.

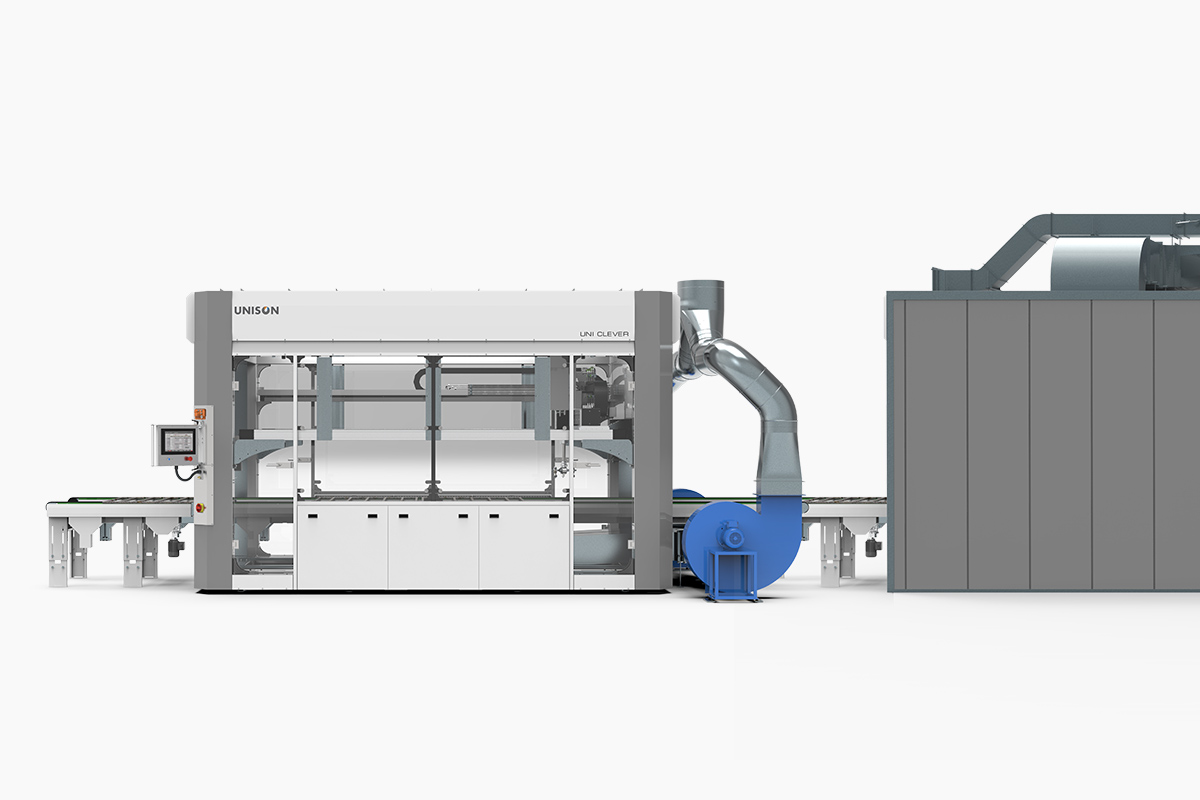

First painting line

The first fully automated painting line is created, consisting of the first version of the UNI-ONE painting machine and the UNI-LEVEL 6 dryer.

Building the new UNISON headquarter

Building the new company's hub and production.

Company portfolio expansion

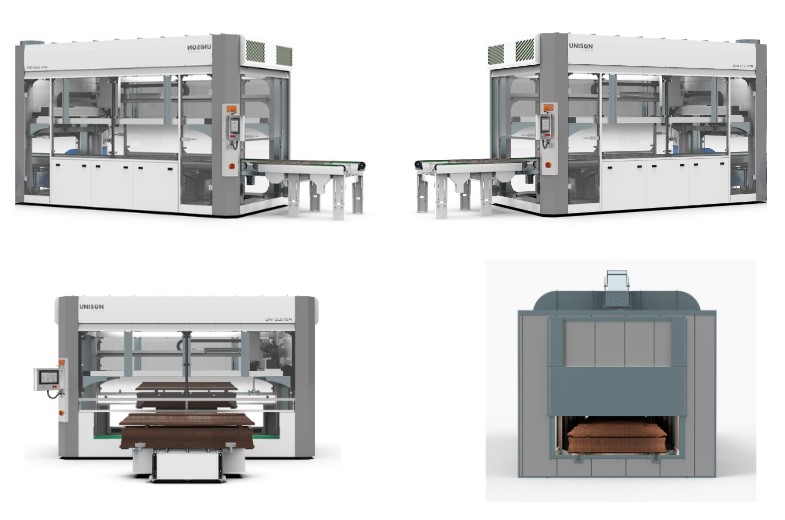

The UNISON portfolio includes painting robots in rotary versions for doors and coffins, as well as those intended for the furniture industry with a main conveyor covered with paper.

New finishing solutions

The company's portfolio is expanding to go through robots for continuous painting works, configurable with dryers. The offer includes robots for coffins, those intended for the furniture industry, equipped with a varnish recovery system, and for varnishing smaller elements, with the option of retrofitting with trays. The first dryer dedicated to the funeral industry is also being built.

Dryer for furniture elements and plastics

In 2020, fully configurable machines were built: the UNI-LIFT H dryer and UNI-CLEVER L/H painting robot. The dryer is created to dry elements placed on the so-called trays.

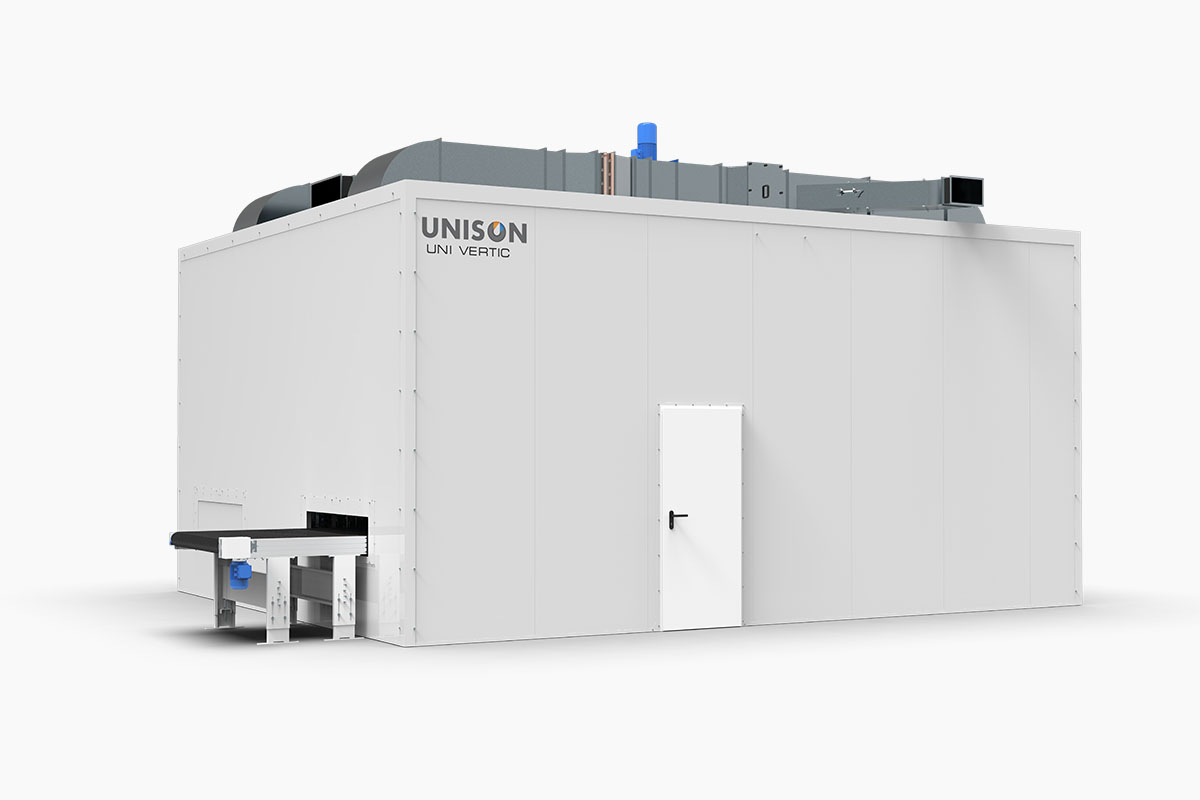

New dryer: UNI-VERTIC

The dryer enabling the installation of up to 34 shelves is created. The volume of shelves allows for even greater improvement in the finishing processes.