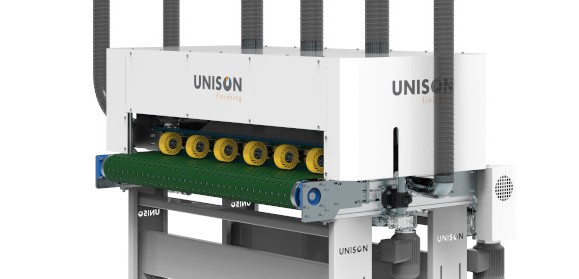

| Working width of the detail cleaning module | 1.350 [mm] |

| Section: BLOWING | |

| Stub pipe dimension | 3 pc. x fi 100 [mm] |

| Section: DIONIZATION | |

| Number of dionizing strips | 2 [pc.] |

| Section: BRUSH | |

| Brush material | Natural fiber |

| Brush stub pipe dimension | 1 pc. x fi 200 [mm] |

| Minimum efficiency of the dust extraction system * | 5.000 [m3/h] |

| Required air flow speed in the dust extraction system* | min. 30 [m/s] |

| * connecting individual sections of the UNI-CLEAN module to an external extraction station or a central system | dust removal unit and ensuring the required flow and efficiency parameters of the exhaust air are provided by the Ordering Party |