- Products

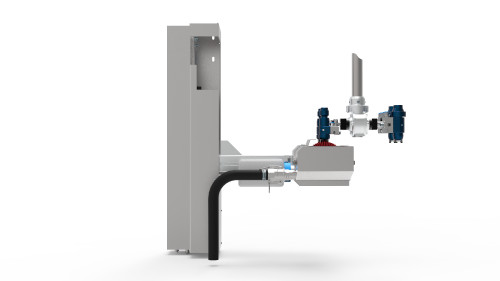

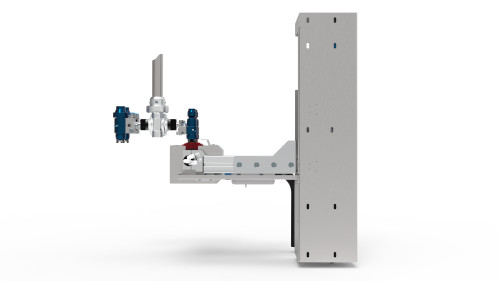

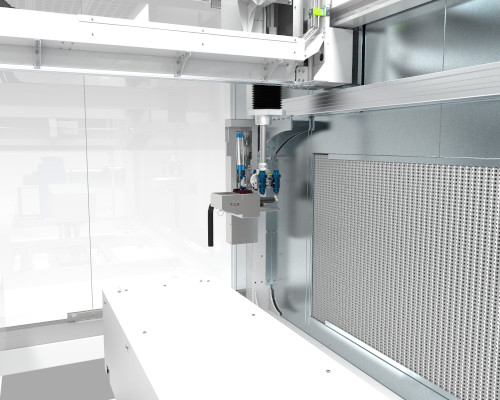

- Finishing robots

UNI-CLEVER - Oscillating machines

UNI-ONE - Painting machines

UNI-SLIM - Dryers

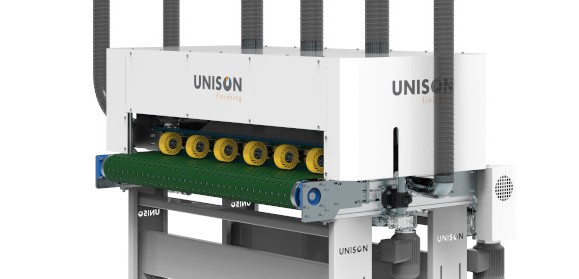

- UNISON Finishing lines

- Grinding robots

UNI-GRIND - Surfaces cleaning stations

powierzchni UNI-CLEAN - Additional devices

- Painting equipment

Finishing robots

UNI-CLEVEROscillating machines

UNI-ONEPainting machines

UNI-SLIMDryersUNISON Finishing linesGrinding robots

UNI-GRINDSurfaces cleaning stations

powierzchni UNI-CLEANAdditional devicesPainting equipment

- Industries

- Company

- Lab

- Training